What is Laser 3D Surface Processing?

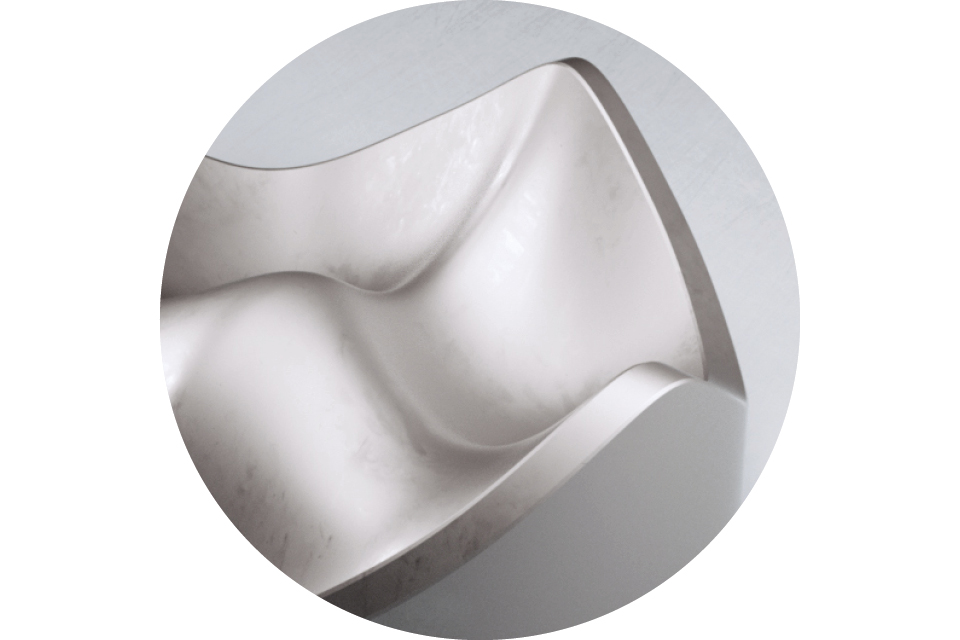

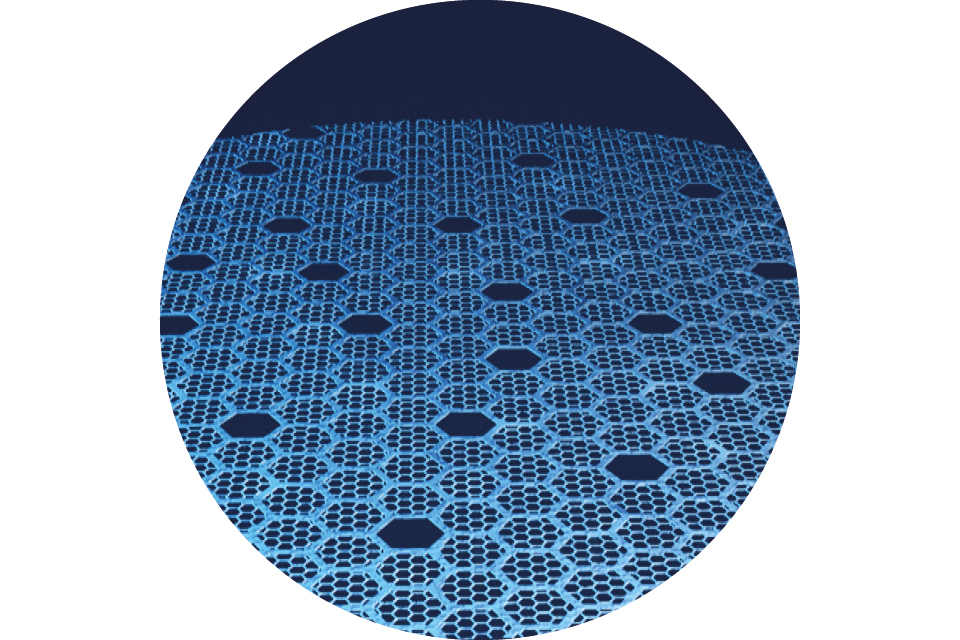

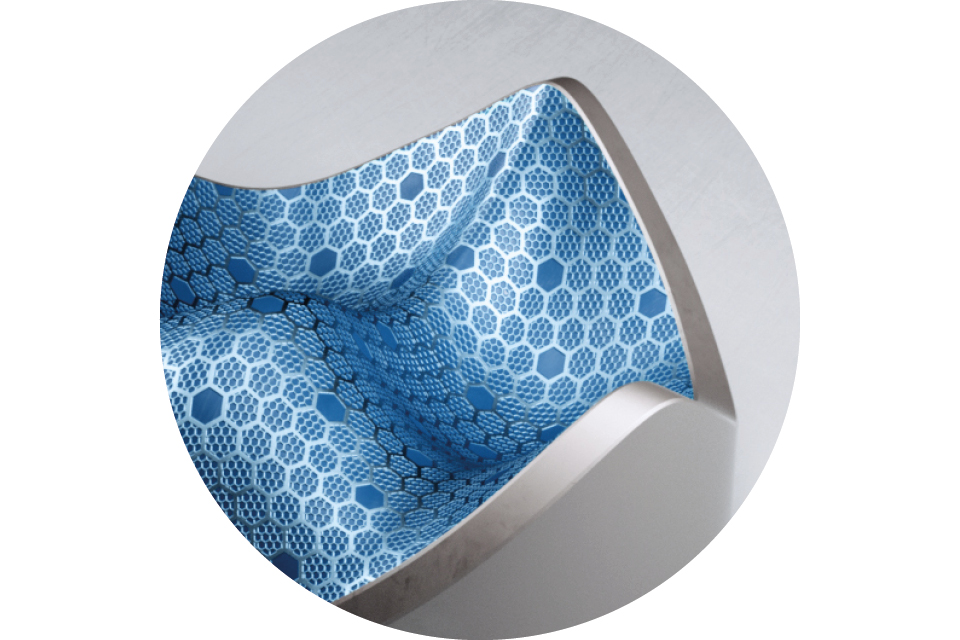

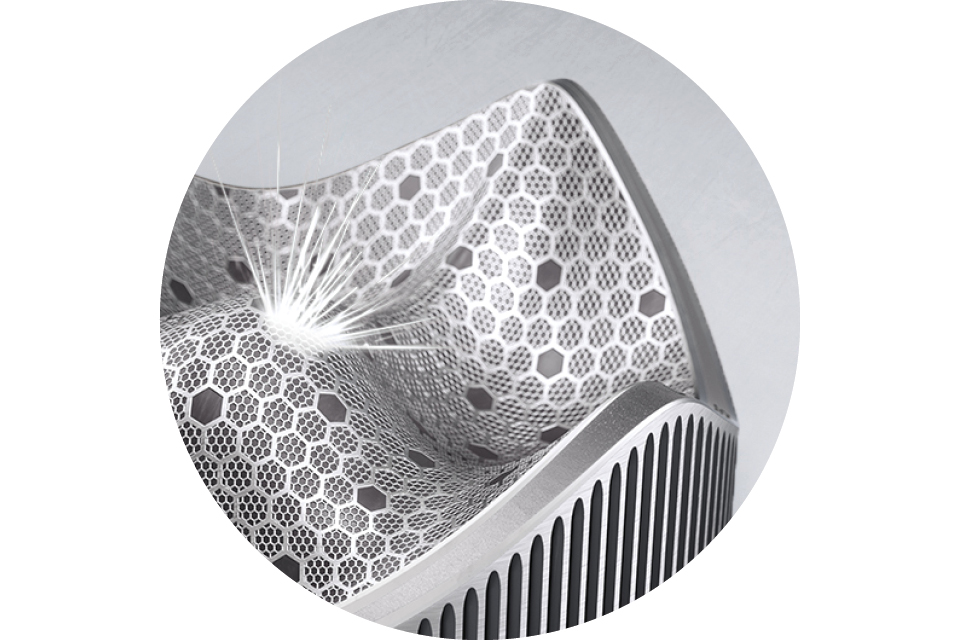

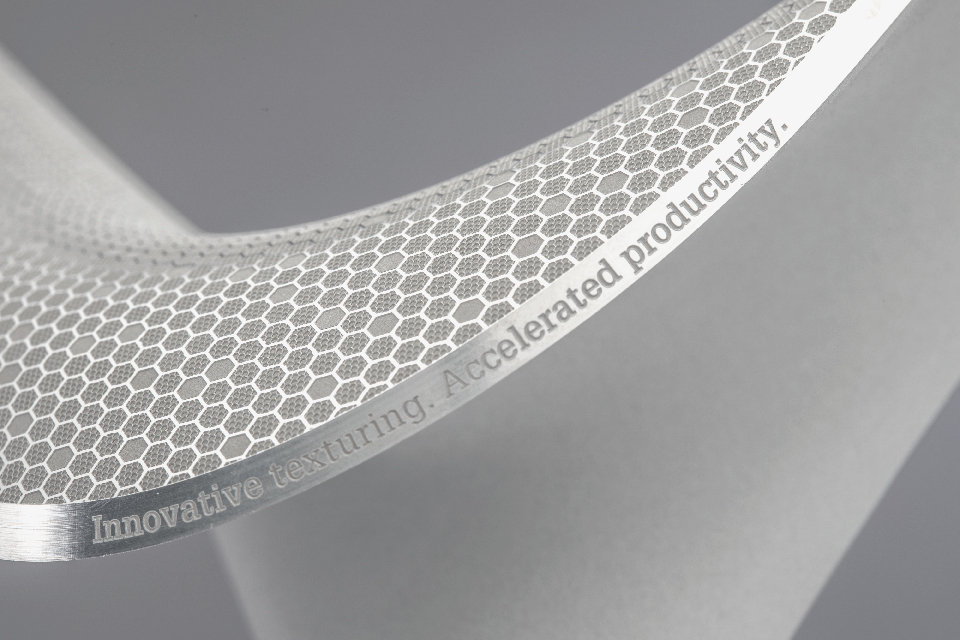

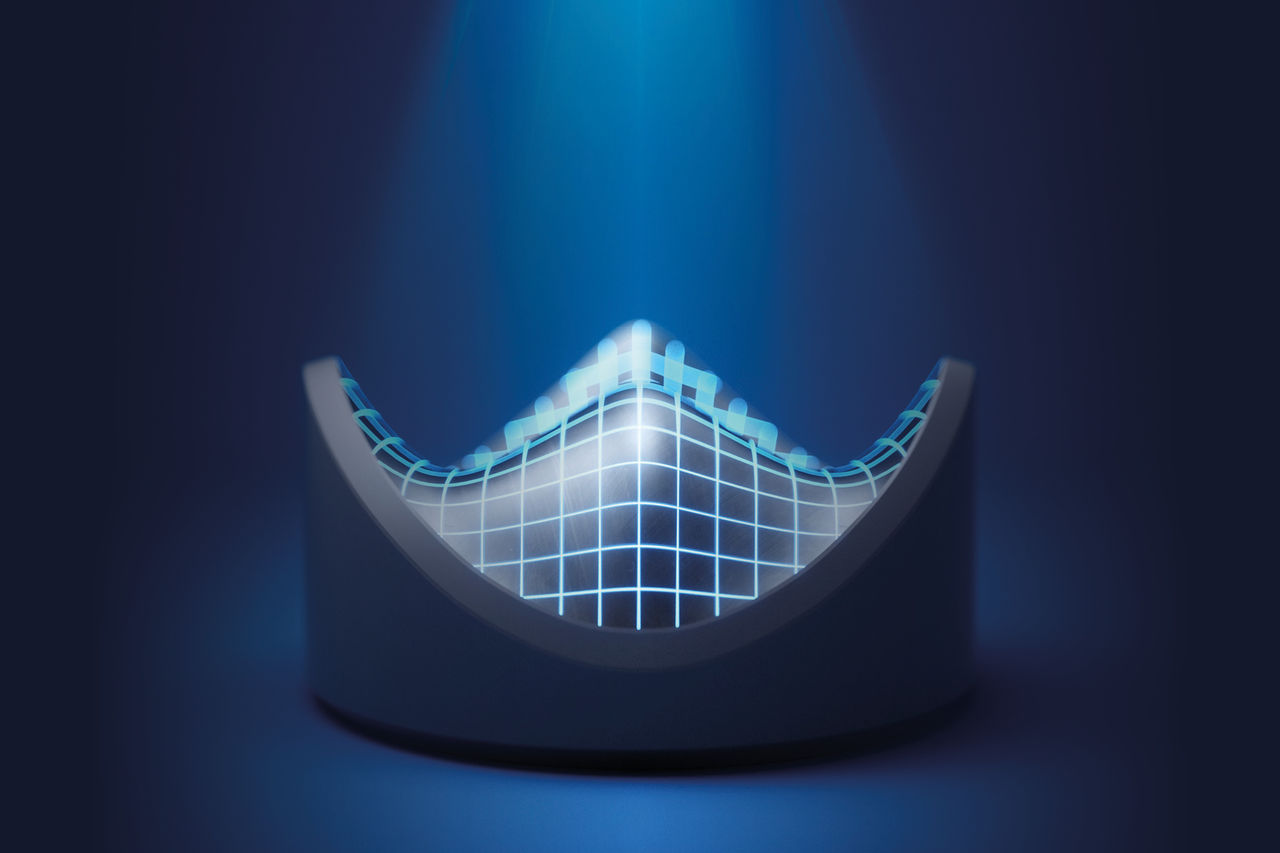

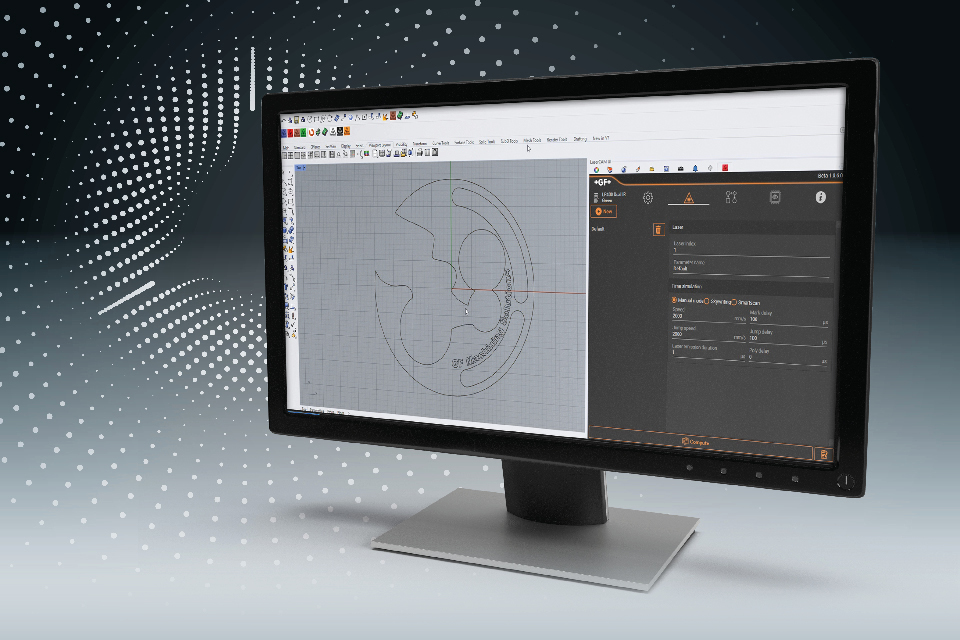

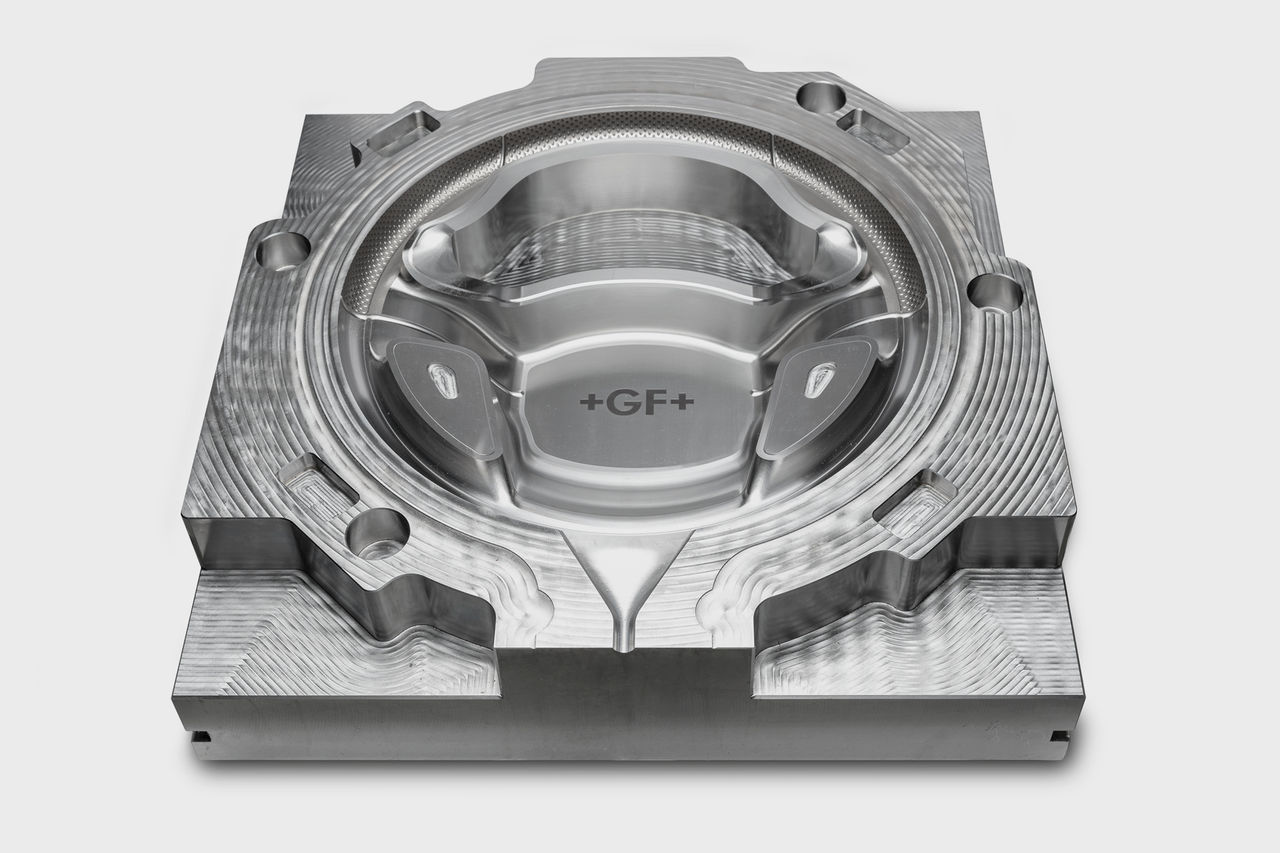

Laser 3D Surface Processing is a fully digital solution that allows creating unlimited effects on the surface of almost any kind of part and material. It is a technology of choice for texturing, blasting, structuring, thin film ablation, as well as decoration and coloring, marking and engraving.

What are the steps of Laser 3D Surface Processing?

Why come to GF Machining Solutions for Laser 3D Surface Processing?

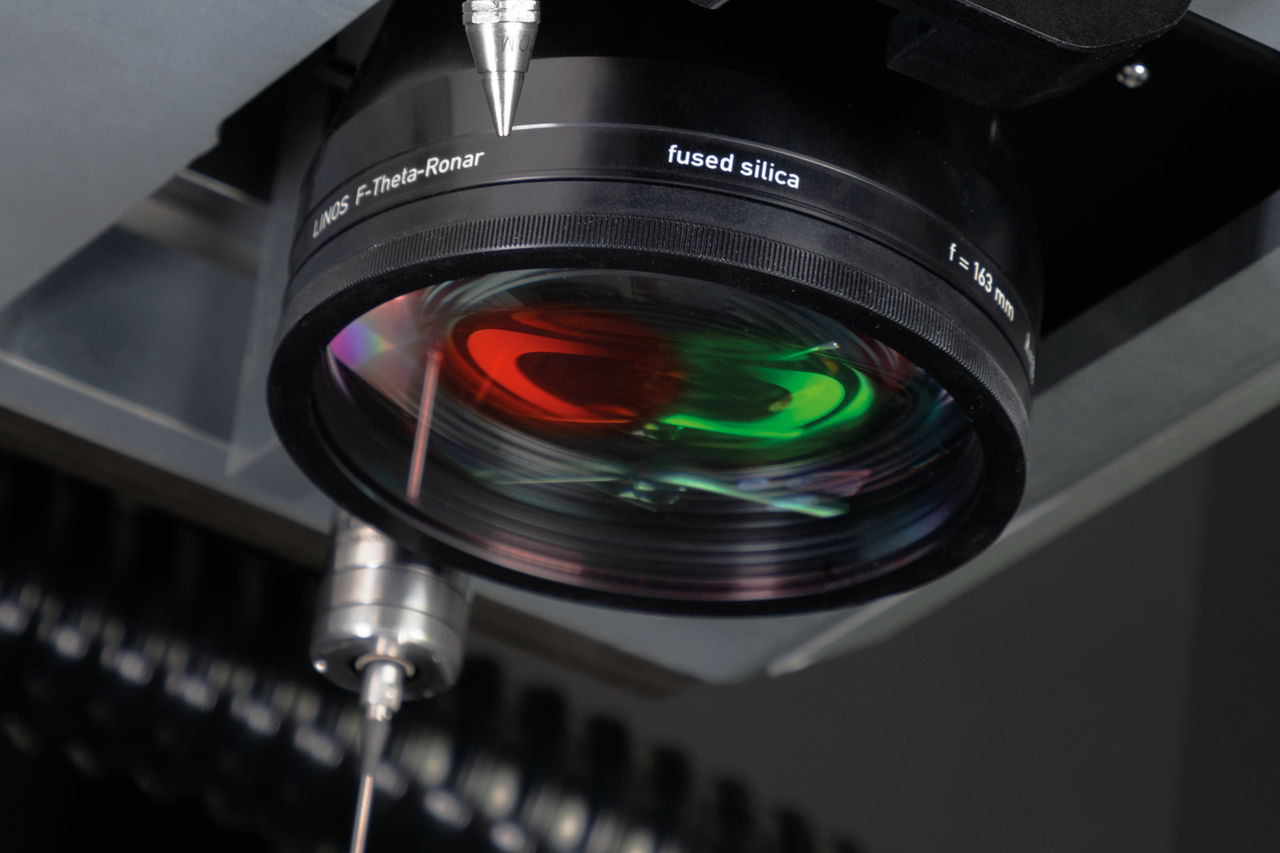

With a strong expertise in software development and photonics, GF Machining Solutions continuously develops high-performance Laser systems inspired by 70 years of experience in state-of-the-art precision machining centers.

In 2008 GF acquired AF Laser, specialized in Laser 3D texturing and since then has constantly innovated in this technology. As of today, GF Machining Solutions is the worldwide leader in Laser 3D Surface Processing.

Thanks to a global presence and unique know-how, GF Laser application engineers and the GF Academy are here to support you and help you realize the full potential of your application with a GF Laser machine.

Main competitive advantages

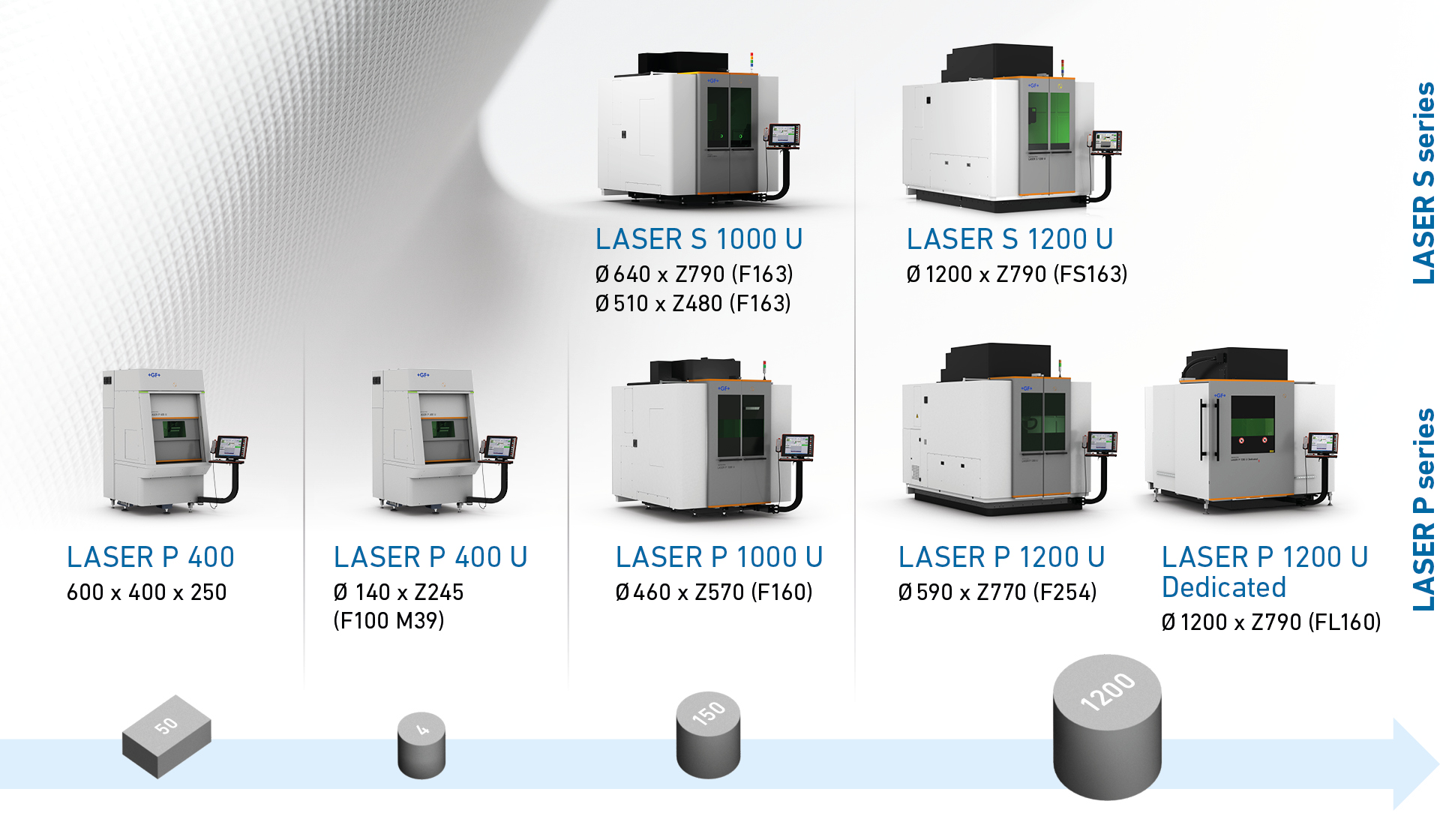

Overview of the series

Our range of Laser machines for 3D Surface Processing

0-1200 kg Table load

1200-18000 kg

LASER S series

Machining volume full 5ax (mm)

Max. part weight (kg)

| Machines | XYZ (mm) Machining volume full 5ax (mm) Max. part weight (kg) |

| LASER S 1000 U | 1000 x 550 x 880 Ø 510 x Z480 with F163 150 |

| LASER S 1200 U | 1200 x 900 x 970 Ø 1200 x Z790 with FS163 1200 |

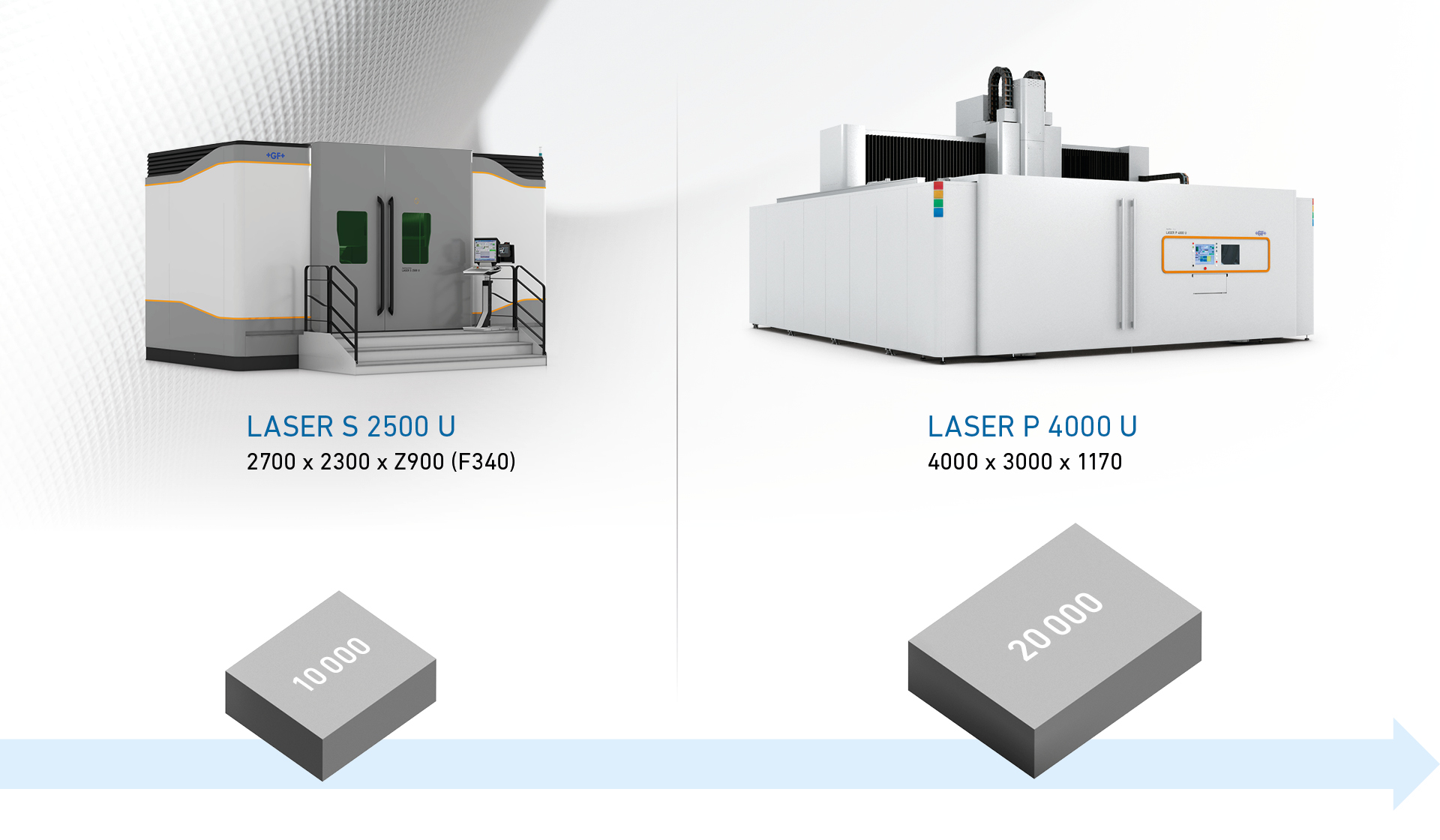

| LASER S 2500 U | 2500 x 2000 x 1200 2700 x 2300 x Z900 * with F340 10000 |

* Max. part size

LASER P series

Machining volume full 5ax (mm)

Max. part weight (kg)

| Machines | XYZ (mm) Machining volume full 5ax (mm) Max. part weight (kg) |

| LASER P 400 | 600 x 400 x 300 600 x 400 x 250 * 50 |

| LASER P 400 U | 600 x 400 x 300 Ø 140 x Z245 with F100 M39 4 |

| LASER P 1000 U | 1000 x 550 x 880 Ø 460 x Z570 with F160 150 |

| LASER P 1200 U | 1200 x 900 x 1200 Ø 590 x Z770 with F254 1200 |

| LASER P 1200 U Dedicated | 1200 x 900 x 1200 Ø 1200 x Z790 * with FL160 1200 |

| LASER P 4000 U | 4000 x 3000 x 1500 4000 x 3000 x 1170 * 20000 |

* Max. part size

Application possibilities

Energy efficiency

With a reduction of 35% of the daily energy consumption compared to the previous generation, our new generation of Laser machines is ready for the future. This high improvement is possible thanks to the 3D scanner instead of a 2D scanner, which allows reducing total axis movements, more powerful Laser sources and SmartPatch and SmartScan software packages.